The pressure switch is a washing machine part located in most models on the side wall, just below the top cover. Its appearance is similar to a washer. Replacing the element is not difficult, but not all technicians are able to perform high-quality repairs of the pressure switch. What are the most common malfunctions of the part, is there a chance to fix them at home without resorting to the services of specialists?

A special code signaling an error helps to detect pressure switch failures in washing machines equipped with a display. It appears on the control panel. There are also other signs indicating malfunctions. Characteristic "symptoms" allow you to suspect failures.

In addition to these signs, poor quality washing may also indicate problems. The laundry may remain dirty because the tank does not collect enough liquid, and the pressure switch setting is incorrect. To fix the sensor malfunction, just turn the special adjustment screw and tighten the spring. Let's take a closer look at how to do this correctly.

Before you start assessing the performance of the pressure switch and start repairing it yourself, you should check whether the warranty period for the washing machine has expired. For most brands, it does not exceed 12 months. If the warranty is still valid, then it is better to avoid self-intervention and contact a specialized center. In other cases, you can repair the water level sensor yourself. To do this, you need to:

After completing these steps, you can check the adjustment of the pressure switch and assess the correctness of its operation. To do this, take a piece of rubber tube and connect it to the sensor. The test method is simple: blow into the tube and observe whether you hear a clicking sound inside the device when the pressure changes. If there is no clicking, the pressure switch is faulty.

The water level sensor is also checked in another way, using hardware. To do this, take a multimeter. Then do the following:

If the contact is triggered, but the resistance value does not change, the sensor is faulty, a new one needs to be installed. Experts advise even if the listed testing methods indicate no breakdowns, it makes sense to conduct an additional inspection of the mechanisms. To do this, attach a tube to the pressure switch and assess its tightness.

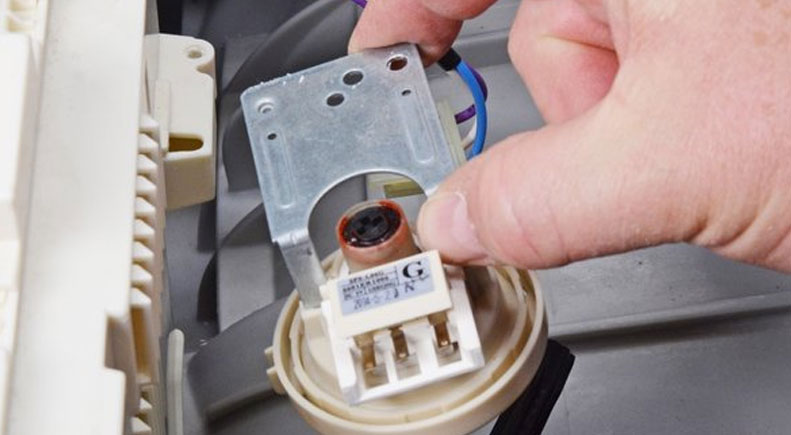

Before you start setting up, you should disconnect the washing machine from the power supply. Then you need to remove the cover, disconnect the connector from the relay. The sensor is equipped with 3 adjustment screws. The one that is designed to control the primary force is in the center of the relay body in most models. The screw is usually made for a Phillips screwdriver. You should only start setting up the sensor when the tank is empty. This work is carried out in several stages, constantly performing intermediate checks of the water level:

These actions are performed several times, with the screw in each case being turned no more than half a turn. In order to independently check, change or adjust the pressure switch, you must have at least basic theoretical knowledge. If you have no experience, it makes sense to contact a professional technician.

Copyright © 2020 Coimbatore Service.