Impurities contained in tap water can “clog” the inlet valve of an automatic washing machine so much that it can only be cleaned after complete disassembly. When a beginner is faced with the job, it seems to him that it is easier to install a new part than to wash the device. This is not true, with due skill you can literally “reanimate” the old part in 15-20 minutes, restoring the machine’s operation.

Some internal parts of washing machines need periodic cleaning. These are all filters, pump, pipes and other elements. Disassembling the valve of a washing machine to clean it is not as difficult as it seems at first glance.

Water is poured into the machine through the inlet valve. Most of the impurities: sand, debris, rust, settle on the inlet filter and membrane. Therefore, it is not surprising that after several years of operation, the washing machine will begin to fill more and more slowly, indicating a clogged part. Different models of washing machines have different valves. Old Samsungs and Indesits have single devices. Modern washing machines usually have double-type parts. Triple and quadruple valves are also found.

The fill valve consists of a coil, a sensitive membrane, a rod, a spring and a mechanism responsible for the operation of the plug. The design functions due to the pressure of the water supply. To check the serviceability of the part, you will need a multimeter. The tester should be switched to the ohmmeter mode and its probes should be applied to the contacts of the element. The working "electromagnet" will give a resistance of 3-4 kOhm.

What else can happen to the inlet valve? When the machine is in a cold room, the water in the device sometimes freezes, and the plastic body of the element cracks. In this situation, it is necessary to install a new part.

If only the inlet filter of the water supply valve is clogged, everything will be even simpler. It is enough to just unhook the inlet hose from the body, use pliers to pull out the clogged mesh, rinse it well and install it back. When the matter is in a deeper blockage, you will have to disassemble the part.

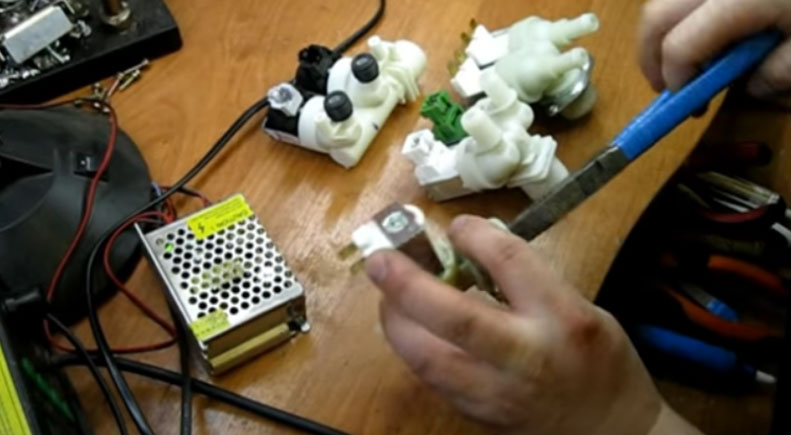

It doesn't matter whether your washing machine has a single, double or triple inlet valve. The disassembly process will be the same in any case. The only difference is that you will have to remove not one coil, but, for example, two, and so on. The following tools will be required during the work:

To disassemble the washing machine valve, you need to:

This completes the disassembly of the SMA inlet valve. Inspect the membrane, it should be intact, without any damage. After cleaning all components, you can assemble the part and check its functionality. Assembly is performed in the reverse order.

The spring is put in place, the membrane is placed, the rod is screwed in. Then the coil is put on manually. To check whether the device works, it is enough to apply 220 volts to the coils.

Old washing machines have slightly different valves, their coil is secured with screws. Therefore, before removing, it is necessary to unscrew all the fastening bolts. The further course of disassembly will be the same: you need to get the rod and clean the membrane with the spring.

Copyright © 2020 Coimbatore Service.