The water level sensor helps the control module control the filling of the washing machine tank. Without this small part, the machine simply will not perform the wash, the cycle will "hang" before it even starts. Let's analyze the device of the washing machine pressure switch, tell you how to diagnose it at home. We will describe the principle of operation of the element.

Modern automatic machines have many components and assemblies. Each part performs a specific function. The pressure switch monitors the water level in the tank. The sensor measures how much liquid is in the "centrifuge", based on the pressure in the tube.

The relay is made in the form of a disk. Inside the pressure switch there is an air chamber with a diaphragm, a magnetic core and a tube. Sensors can be of a simple and complex type, differing in membrane sensitivity and rod stroke.

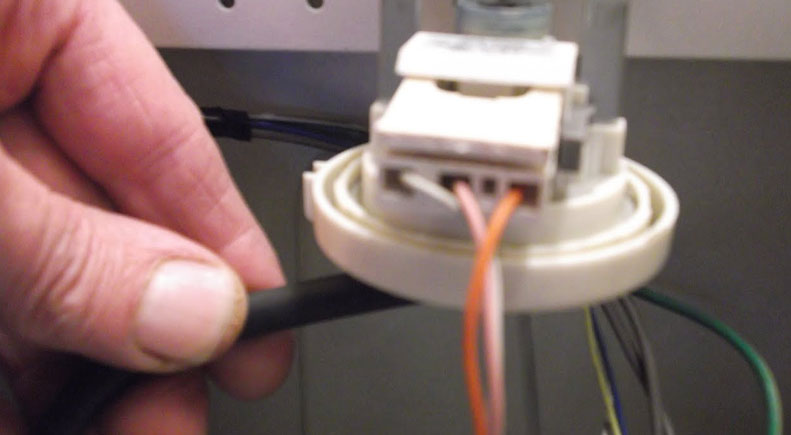

The pressure switch from one machine does not always fit another washing machine. Therefore, if the factory sensor is broken and requires replacement, be sure to look for and buy an analogue, focusing on the model and serial number of the machine. The "shell" of the pressure switch is made of high-quality plastic. Externally, the relay resembles a washer. The sensor is assembled from the following components:

Depending on the model of the automatic machine, the pressure switch should be looked for in different places. The water level sensor is installed:

Now it is clear how the pressure switch is arranged and in which part of the washing machine to look for it. We will also analyze the operating principle of the level sensor. We will tell you what its role is in an automatic machine.

A pressure switch is provided in any automatic washing machine. It is necessary to control the water level. The sensor sends a signal to the "brain" of the washing machine, notifying the controller about the degree of filling of the tank. This information is used by the module to control the washing.

The sensor membrane is very sensitive. Under pressure, the rod rises and presses on the plate with the spring. When the water in the tank reaches the required level, the circuit is closed. The pressure switch notifies the module that there is enough water, and the controller starts the next "step" of washing. At the drain stage, the pressure in the pressure switch tube decreases, the rod begins to descend together with the plate. The electrical circuit is broken.

You can tell that the water level sensor is not functioning correctly by a number of signs. Firstly, this is the error code displayed on the machine's display. If the self-diagnostic system has not detected a malfunction, you should suspect a malfunction of the pressure switch when:

Having noticed one or more "symptoms", it is better not to "torment" the machine further, but to check the pressure switch. It is not always necessary to change the water level sensor, sometimes it is enough to clean and adjust it. Let's figure out how to diagnose the element.

Before you disassemble the body of the washing machine with your own hands, check whether the machine is under warranty. If the free service period has not yet expired, it is better to invite a specialist for diagnostics. If you do unauthorized repairs, you can forget about warranty service.

If the warranty for the device has long expired, you can start self-diagnosing. You should do the following:

Before changing or adjusting the device, you should check it for proper operation. To do this, you will have to prepare a short rubber tube, the same as on the pressure switch. After removing the water level sensor, connect the prepared tube to it. Then blow into it - if the pressure switch is working, you should hear two or three characteristic clicks. Silence will indicate that the contacts are not working, therefore, the relay is faulty.

Next, inspect the pressure switch, make sure it is not damaged. Also check the hose for blockages - if it is clogged, blow it out or rinse it under running warm water.

Hardware testing of the pressure switch is considered more accurate. To perform diagnostics, switch the multimeter to ohmmeter mode and apply the device probes to the relay contacts. Be sure to create pressure in the tube so that the contacts work. If the numbers on the tester screen do not change when the contacts work, you will have to replace the pressure switch. When everything is working properly, you can not buy a new sensor, but simply adjust the existing one.

The pressure switch is adjusted manually. The adjustment will help if too little water is collected in the machine during washing. The volume of liquid can be made smaller or larger - for this, it is necessary to set the response force of the relay. Before starting the procedure, it is necessary to de-energize the equipment.

Remove the top cover of the machine, find the pressure switch and reset the connector. The level sensor has 3 adjustment bolts, one of which will have to be tightened in the process. The screw used to make the adjustment is usually located in the central part.

You can tighten the screw with a Phillips screwdriver or an "asterisk". The procedure is carried out in stages - it is important to evaluate the intermediate results of the sensor settings. So, you need to turn the bolt half a turn, then assemble the machine and run a test cycle with an empty drum. If the results are not satisfactory, you need to turn the screw again.

It is necessary to adjust the pressure switch with at least minimal basic theoretical knowledge. If you have no idea at all how the level sensor works, it is better to entrust the work to a specialist. The specialist will correctly adjust the relay.

Copyright © 2020 Coimbatore Service.